The key to Tandem Building Products™ innovation lies in the patented design of the Tandem® Series™. Where conventional roofing panels are screwed down to a building’s infrastructure, TBP™ panels are inverted and attached to the system, allowing for protection against weather elements and natural disasters. Below is a comparison of the commercial roofing industry’s current types of roof systems to include metal and low slope (or flat) roofs.

Conventional Metal Roofs

Conventional Metal Roofs

Two common types of conventional metal roofs include R-Panel and Standing Seam.

R-panel, or exposed fastener roofing, consists of overlapping panels that are fastened directly to the roof deck or framing through the face of the metal. They are called “exposed” because the fastener head remains visible once installed. The ribs (trapezoidal design seen in the drawing to the right and the animation below) give the classic ribbed appearance on R-panel metal roofs.

Conventional Fasteners

In this profile view, screws are drilled straight down through the metal R-panel into the roof deck. Over time as the metal expands and contracts from heat and cold, screw holes will grow wider, causing leaks. Water ponding on the roof in low places will also cause rusting and leaks. In strong storms, the forces of high winds will lift and PULL OUT the screws and roof.

Characteristics of Conventional Metal Roofs

CORROSION

TBP™ DIFFERENCE

CONTRACTION AND EXPANSION

TBP™ DIFFERENCE

CAN'T BE USED FOR LOW SLOPE ROOFS

TBP™ DIFFERENCE

DENTS EASILY, HARD TO REPAIR

TBP™ DIFFERENCE

Characteristics of the Tandem® 300™ System

QUICK INSTALLATION

TBP™ ADDED PROS

DURABILITY

TBP™ ADDED PROS

LONGER LIFESPAN

TBP™ ADDED PROS

ENERGY EFFICIENT

TBP™ ADDED PROS

Conventional Low Slope Roofs

Conventional Low Slope Roofs

Conventional low slope roofs (“flat roofs”) are not able to utilize metal panels. Instead, they use soft membranes including plastic, rubber, and modified bitumen.

Types of Low Slope Roofs

Built-Up Roofing: BUR alternates layers of asphalt and fabric with a top layer of stone or aggregate.

Rubber Membrane Roofing: also known as EPDM, is made of a thick rubber layer secured with roofing glue and metal anchors.

Modified Bitumen: similar to BUR roofing, is installed in pre-made sheets rather than building up layers on-site.

Single-Ply Roofing: utilizes a single-ply thermoplastic system that usually has a white UV-reflective color.

Cons

PONDING WATER

TBP™ DIFFERENCE

CONTRACTION AND EXPANSION

TBP™ DIFFERENCE

CAN'T BE USED FOR LOW SLOPE ROOFS

TBP™ DIFFERENCE

DENTS EASILY, HARD TO REPAIR

TBP™ DIFFERENCE

Pros

SAFE INSTALLATION

TBP™ ADDED PROS

SOLAR PANELS

TBP™ ADDED PROS

LESS MATERIALS NEEDED

TBP™ ADDED PROS

ENERGY EFFICIENT

TBP™ ADDED PROS

The Tandem® Series™

The Tandem® Series™

The Tandem®Series™ of resilient metal roof and wall systems are uniquely suited to protecting assets in hurricane, tornado and other wind-damaging conditions/events.

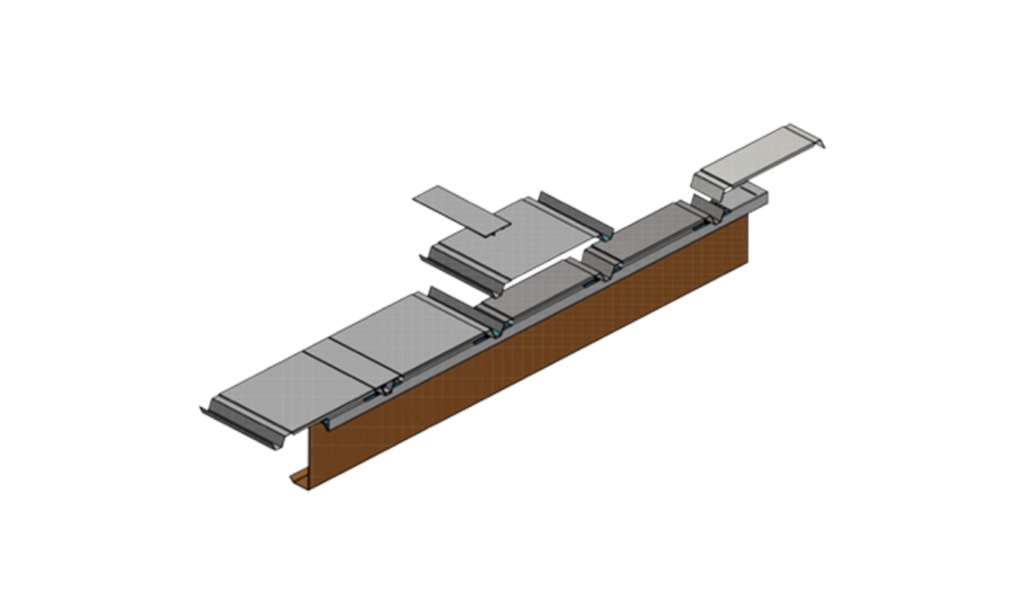

The system is engineered to have a useful life of 100 years and allows for a 5x stronger attachment to infrastructure members compared to conventional metal roof/wall systems. The attachment system accommodates expansion and contraction movement in 360 degrees, which means the panels are not subjected to stress or binding.

This free movement of panels supports the use of heavier gauge metal. While conventional metal roofs and walls are limited to 22-gauge maximum, the Tandem®300™ supports a range of sheet metal gauges. The Tandem® attachment system can be used on all types of infrastructure, including Z and C purlins, web joists, wood or metal rafters, and studs.